Heckert Original.

Fall Protection

Heckert Original Fall Protection

Fall Protection

Fall protection according to Performance Level "d" is sufficiently realized with our double motor solution. Performance Level "d" is implemented through SLS (Safely Limited Speed) and STO (Safe Torque Off), and every motor brake is designed with double braking torque so that if one motor fails, the second motor can hold the load. Our flat belts are designed with a safety factor against breakage of >10, meaning one belt could fail and the remaining belts can still hold and move the load in compliance with the operating specifications of EN 1570-1. A maximum of 10% of the breaking force (at least S > 10) is used. The belt manufacturer allows 30%, the standard requires max. 20%.

- Another solution is the pneumatically actuated safety brake SITEMA type KSP 28.

- Load direction: PRESSURE on the fastening of the clamping rod, the spread shaft of the lift table

- SAFETY BRAKE SITEMA KSP 28 acts by design only during downward travel of the lift table!

- When the lift table moves up, the load acts against the required load direction, and the lift table is not braked in this case!

- When the lift table is raised, the clamping rod always remains in a horizontal position because the end of the rod runs concentrically with the clamping ring on the spread shaft.

- Function as emergency brake during downward travel of the lift table:

- Dynamic braking of the load in case of motor brake failure or in the unlikely event of simultaneous breakage of several flat belts.

- The catching device (catch brake) required by EN 1570, section 5.7.5, which limits the lowering of the platform to 100 mm in the event of any part of the lifting mechanism breaking and holds the platform, is realized by the SITEMA safety brake.

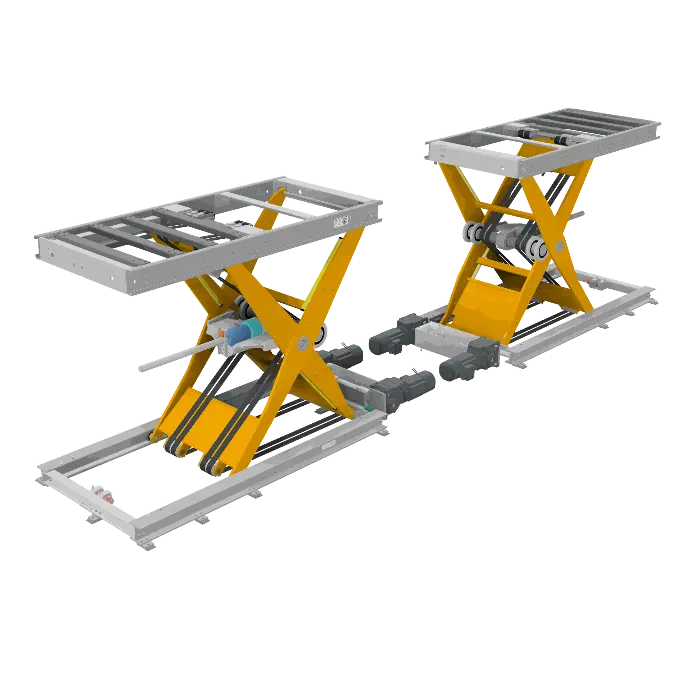

Tandem with Fall Protection

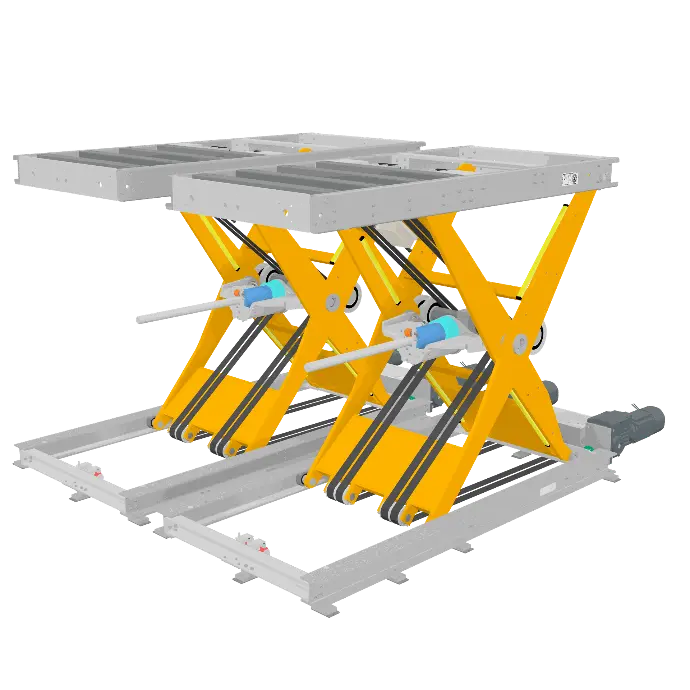

Double Motor with Fall Protection

Standard with Fall Protection